Hog Farm Lagoon – with treated pull-pits.

Managing manure in livestock operations is a complex challenge, with problems related to polluted water, odors, and decreased livestock health in enclosed areas. By introducing beneficial biological agents, producers can enhance manure liquefication in pull-pits, streamline manure pumping, reduce odors, control ammonia emissions within enclosed barns, and promote healthier lagoon ecosystems downstream.

Bioaugmentation in Pull-Pits: Enhancing Liquefication and Pumping Efficiency

Traditional manure handling can be plagued by thick solids and uneven liquefication, making pumping cumbersome and inefficient. The addition of biologicals—carefully selected microorganisms—accelerates the breakdown of organic matter, reducing solids and creating a more fluid slurry. This enhanced liquefication leads to:

- Easier and more effective pumping

- Decreased risks of blockages and costly maintenance issues

- A reduction in unpleasant odors and ammonia levels, improving air quality within livestock housing

Extending Biological Activity to Downstream Lagoons

When treated manure moves from pull-pits to lagoons, the biological activity initiated upstream continues to work its magic. In lagoons, beneficial microbes facilitate ongoing decomposition and minimize sludge accumulation. The key benefits include:

- Sludge Reduction – Biological agents further digest organic solids, preventing excessive buildup and reducing dredging requirements.

- Improved Water Quality – Enhanced breakdown of waste materials results in cleaner water, which is crucial for irrigation applications.

- Odor Control – A healthier microbial balance leads to fewer volatile compounds, reducing unpleasant smells that can impact neighboring communities.

Creating & Testing Pull-Pitt Treatment Formulation

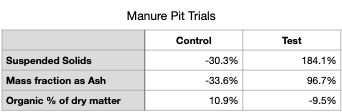

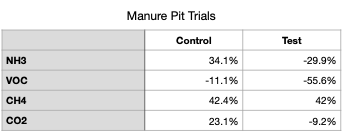

Aster Bio began developing manure formulations by looking at the problems associated with solids, in-house air quality, and odor complaints from local communities. We looked at how biological solutions could prevent crust formation and anaerobic zone formation where ammonia, hydrogen sulfide (H2S), and other malodors form. After surveying pull-pits, we began testing a product with data recorded for all key parameters. The test was run for 4 weeks with % change in parameters noted in following charts.

Note how adding microbial blend to the pull-pits reduced the crust layer and liquefied the solids into suspended form. The total % as organic matter decreased with a corresponding increase in ash (non-volatile). The other part of the test included atmospheric analysis for key paramters. We noted a decrease in Ammonia and VOCs in the atomosphere.

Better Sustainability Through Biological Treatment

By integrating biological treatment into manure management systems, producers unlock a more sustainable approach to handling waste. The improved efficiency, odor reduction, and water quality benefits contribute to better environmental stewardship while optimizing operational effectiveness.

Whether in pull-pits or lagoons, biological enhancement is proving to be a powerful solution for modern manure management. Investing in the right technologies can make all the difference in keeping systems running smoothly while promoting a cleaner, healthier agricultural operation.