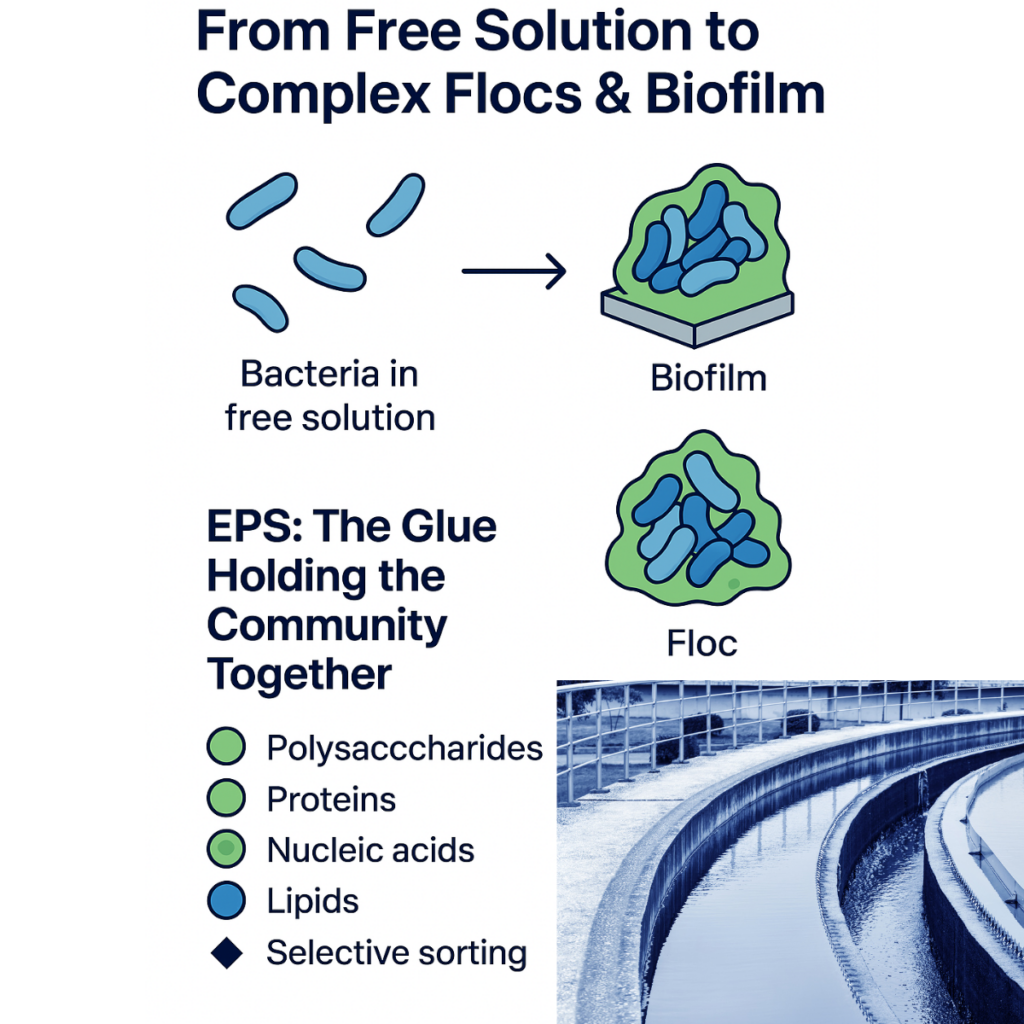

In the bustling microcosm of a wastewater treatment plant, bacteria don’t just float around aimlessly—they evolve, interact, and build structured communities that play critical roles in purification processes. Two major forms of bacterial aggregation dominate: flocs and biofilms. While they differ in architecture and environmental niche, their formation hinges on shared biological principles, especially the growth phase of bacteria and the secretion of extracellular polymeric substances (EPS).

Floc vs. Biofilm: What’s the Difference?

| Feature | Floc | Biofilm |

| Structure | Loosely bound aggregates | Dense, layered structures on surfaces |

| Habitat | Suspended in bulk liquid | Attached to surfaces (media, walls) |

| Formation Speed | Rapid under favorable conditions | Often slower, but highly resilient |

| Role in Treatment | Key in activated sludge processes | Dominant in biofilters, MBBRs, IFAS |

Growth Phase: The Transition from Free-Living to Aggregated

The ability of bacteria to aggregate is deeply influenced by their physiological state:

- Lag Phase: Cells are metabolically active but not dividing. EPS production may begin here as part of environmental sensing.

- Log (Exponential) Phase: Rapid growth often inhibits aggregation—cells are busy dividing and may express anti-adhesion proteins.

- Stationary Phase: Nutrient limitations and stress response activate genes responsible for adhesion and EPS synthesis, making this phase a hotbed for floc and biofilm initiation.

- Decline Phase: Dead or lysed cells contribute organic matter that may seed further aggregation or biofilm layering.

In engineered systems, optimizing conditions to tip populations toward stationary-phase behaviors can boost floc strength and improve settleability.

EPS: The Biological Glue Holding It All Together

EPS—primarily composed of polysaccharides, proteins, nucleic acids, and lipids—is the secret sauce in microbial aggregation:

- Adhesion: EPS promotes cell-to-cell binding and anchorage to surfaces.

- Hydrophobic Interactions: These help in cluster formation and floc compaction.

- Protection: It forms a shield against shear stress, toxins, and predators like protozoa.

- Selective Sorting: EPS composition can influence which species co-aggregate—critical for maintaining functional consortia in BNR systems.

Recent studies suggest that manipulating EPS characteristics through operational controls (e.g. SRT, pH, DO) can steer microbial behavior toward desired outcomes like better sludge dewaterability or enhanced nutrient removal.

Engineering Implications

Understanding how microbial growth stages and EPS dynamics contribute to floc and biofilm formation unlocks major process optimizations:

- Floc Strength & Settleability: Essential for clarifier efficiency

- Biofilm Stability & Retention Time: Crucial for fixed-film systems

- Control Strategies: Bio-augmentation, selective wasting, or adjusting loading rates to favor desired growth stages